- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 7 Author: Site Editor Publish Time: 2022-09-30 Origin: Site

What is automotive wiring harness

Automotive wiring harness is the main body of the automotive circuit network, without which there is no automotive circuit. At present, whether it is a senior luxury car or an economical ordinary car, the form of car wiring harness is basically the same, which is composed of wires, connectors and winding tape.

Automotive wire specifications

Automotive wire, also known as low-voltage wire, wire for copper multi-core flexible wire commonly used specifications are 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 4.0, 6.0 square millimeters, each allowable load current value.

Take the whole vehicle wiring harness as an example.

0.5 wire for instrument lights, indicator lights, door lights, dome lights, etc.; 0.75 wire for license plate lights, front and rear lights, brake lights, etc.; 1.0 specification wire for turn signal lights, fog lights, etc.

1.5 gauge wire for headlights, horns, etc.

The main power cord requires 2.5 to 4 square millimeter wires. The key is to look at the maximum current value of the load, such as the battery override wire, the positive power wire is a special car wire used separately, they are more than ten square millimeters of wire diameter.

Classification of automotive wiring harness

The main wiring harness is generally divided into engine (ignition, EFI, power generation, starter), instrumentation, lighting, air conditioning, auxiliary appliances and other parts, with the main harness and branch harness.

The main wiring harness of the whole vehicle often takes the instrument panel as the core part and extends before and after. It is divided into front wiring harness (including instrumentation, engine, headlight assembly, air conditioning, battery), rear wiring harness (tail light assembly, license plate light, luggage compartment light), roof wiring harness (door, roof light, audio speaker), etc.

Standard Automotive Wiring Harness Circuit

The most basic automotive wiring harness typically contains 12 "circuits" or lengths of wire for a specific purpose, with a designated fuse holder in the fuse box for each circuit:

• Radio

• Wipers

• Turn signals

• Gauges

• Parking lights

• Horn

• Hazard flasher

• Tail light

• Parking lights

• Dashboard Lights

• Dealership

• Heating and Air Conditioning

Each circuit listed serves an important or extremely common electrical accessory, which is why most wiring harnesses come with at least 12 circuits. However, many vehicles have other electrical accessories in addition to those listed. An 18-circuit harness can add 6 circuits to a power accessory, such as

• Power windows

• Power locks

• Electric fans

• Electric fuel pump

• High-mounted parking lights

• Radio B+ memory

A 24-circuit wiring harness will add wiring to support additional accessories:.

• Under hood lights

• Bell

• Lighter

• Dome light

• Trunk light

• Glove box lights

As you can see, the number of circuits required for a wiring harness depends on the electrical accessories you have (or want to have) in your vehicle

Marking

The symbols on the numbers and letters on the end of the harness to mark the connection of the wire objects, the operator can see that these symbols are correctly connected to the corresponding wires and electrical devices, facilitating the repair or replacement of the harness; or the same circuit is distinguished by the color of the wire

The color of the wire is divided into single-color wire and two-color wire, the use of color is generally the standard set by the car manufacturer.

Winding method of automotive wiring harness

The surface of the wire harness has different winding methods according to the different parts of its use.

Engine harnesses work in harsh environments, so all of them are wrapped with threaded tubes that are highly flame-retardant, waterproof and of high mechanical strength.

The front cabin wire also works in a poor environment, most of the branches are also wrapped with threaded pipe with good flame retardancy, and some branches are wrapped with PVC pipe.

Instrument wire working space is small, the environment is better, available tape full wrap or flower wrap.

Door line and roof line working space is small, available tape full wrap, part of the branches available industrial cling film; finer roof line can be directly glued to the body with sponge tape.

Chassis line because of more parts in contact with the body, so the use of bellows wrapped to prevent the harness wear damage.

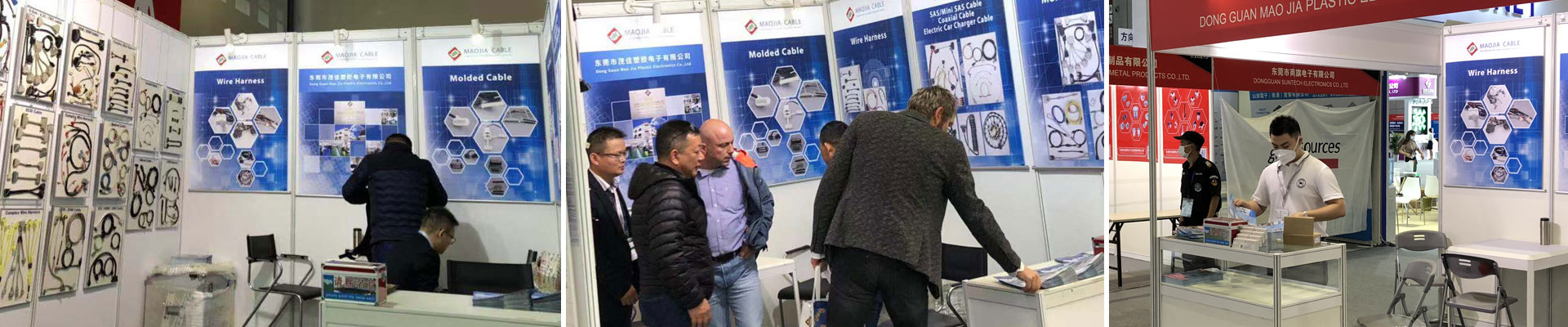

If you have a need for custom automotive wiring harness, welcome to contact the professional wiring harness manufacturer Maojia.