- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 44 Author: Site Editor Publish Time: 2023-03-27 Origin: Site

In industrial automation, robots are essential tools to perform various tasks accurately and efficiently. They can lift heavy loads, assemble products, and even operate machines. However, a robot needs to be connected to a control system that sends commands and receives feedback for a robot to function correctly. This connection is made possible by a device known as a robot harness.

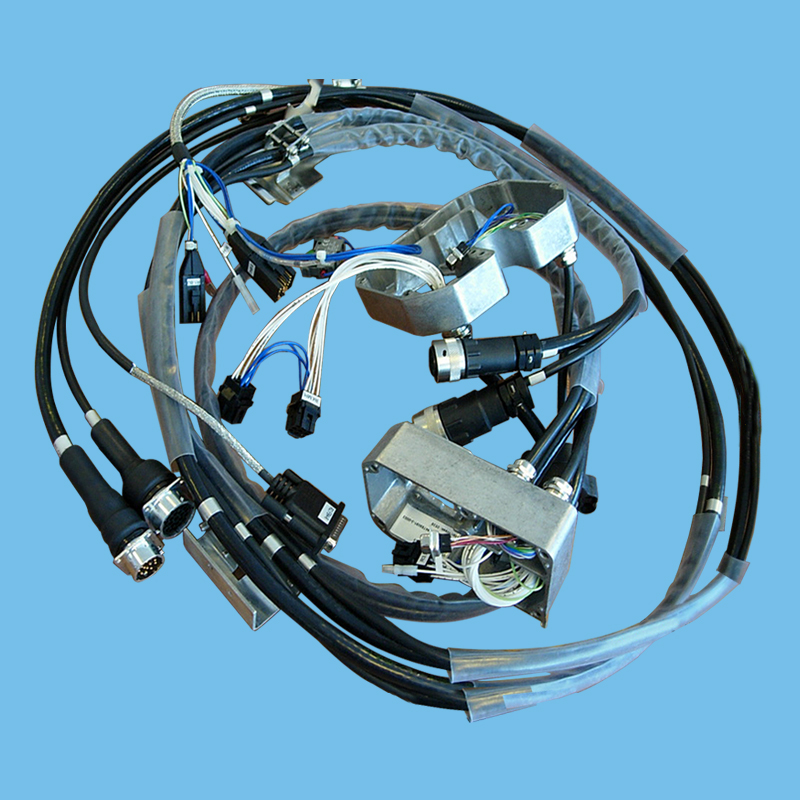

A robot harness is a specialized cable assembly that connects the robot's motors, sensors, and other components to the control system. It consists of multiple bundled cables, providing a streamlined and organized system for transmitting signals and power to and from the robot. Custom robot harnesses are designed to meet the specific needs of a particular robot, ensuring that it functions optimally in its intended application.

Robot harnesses are designed and manufactured by companies that specialize in this field. A robot harness manufacturer will work closely with the client to understand their robot's requirements and then design and produce a custom harness that meets them. The manufacturer must ensure that the harness is durable, reliable, and can withstand the harsh conditions of the industrial environment.

A robot harness's main function is to connect the robot and its control system. The harness consists of multiple cables that carry signals and power to and from the robot's components. These components include the motors that drive the robot's movements, sensors that detect environmental changes, and other devices that perform specific functions.

Each cable in the harness is color-coded and labeled to ensure it is connected to the correct component. The cables are also shielded to prevent interference from other electrical devices and protect them from environmental damage such as heat, moisture, or chemicals.

The harness connects to the robot's components using specialized connectors designed to provide a secure and reliable connection. These connectors are often custom-made to fit the specific requirements of the robot and the control system. Once the harness is connected, the robot can send and receive signals and power to and from the control system.

Custom robot harnesses offer several benefits over generic harnesses or other types of connections. Some of these benefits include:

1. Improved performance: Custom harnesses are designed to meet the specific requirements of the robot and the control system, ensuring they function optimally.

2. Greater flexibility: Custom harnesses can be designed to fit the specific layout and configuration of the robot, providing greater flexibility in its movements.

3. Increased durability: Custom harnesses are designed to withstand the harsh conditions of the industrial environment, making them more durable and reliable.

4. Enhanced safety: Custom harnesses are designed to meet safety standards and regulations, ensuring that the robot and the control system operate safely.

Robot harnesses are essential components of industrial automation, connecting the robot and the control system. Custom robot harnesses offer several benefits over generic or other types of connections, including improved performance, greater flexibility, increased durability, and enhanced safety. A robot harness manufacturer can work closely with the client to design and produce a custom harness that meets their specific requirements, ensuring the robot functions optimally in its intended application.