- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 45 Author: Site Editor Publish Time: 2023-03-30 Origin: Site

The need for smaller and more versatile electronic devices is increasing as technology evolves. The use of custom flat cable has become an attractive solution for many designers, engineers, and manufacturers due to its unique features. This article will discuss the advantages and disadvantages of flat cables for electronic devices.

One of the most significant advantages of the custom flat cable is its space-saving design. This cable type has a low profile and can fit into tight spaces that round cables cannot. This makes it ideal for use in electronic devices where space is at a premium.

Another advantage of the flat cable is its flexibility. Due to its design, it can bend and flex in different directions without breaking or damaging the conductors. This flexibility makes it ideal for applications where cables need to move and bend frequently.

Flat cables can have multiple conductors in a small cross-sectional area, making them ideal for high-density interconnects. This means that they can carry more signals per unit area than round cables, making them an excellent choice for electronic devices requiring many connections in a small space.

Flat cables are also easy to terminate. The conductors are arranged side by side, which makes it easy to connect them to connectors and other components. This makes them an attractive option for designers and manufacturers who need to make a large number of connections quickly.

Lastly, the flat cable is a cost-effective solution for electronic devices. Its simplicity makes it can be manufactured in large quantities cheaply. This makes it an excellent choice for manufacturers who need to produce many electronic devices quickly and cost-effectively.

One of the main disadvantages of the flat cable is its limited voltage and current capacity. Due to its design, it has a smaller cross-sectional area compared to round cables. It cannot handle as much current or voltage as round cables. This makes it less suitable for applications that require high power.

Another disadvantage of the flat cable is that it can be difficult to repair. If a conductor in a flat cable is damaged, locating and repairing the fault can be challenging. This can make it more expensive to repair than round cables.

Flat cables can also have signal integrity issues. Due to the proximity of the conductors, crosstalk, and interference can occur between them. This can cause signal degradation and affect the performance of the electronic device. This makes the flat cable less suitable for high signal quality applications.

While flat cable is flexible, it has limitations. It cannot bend or flex as much as round cables, and if bent too far, it can cause damage to the conductors. This makes it less suitable for applications that require a high degree of flexibility.

Lastly, flat cable has a limited temperature range. It cannot handle extreme temperatures as well as round cables. This makes it less suitable for use in applications where high temperatures are a concern.

In conclusion, custom flat cable has advantages and disadvantages that designers, engineers, and manufacturers must consider when selecting the right cable for their electronic devices. Its space-saving design, flexibility, high-density interconnect, ease of termination, and cost-effectiveness make it an attractive option. However, its limited voltage and current capacity, repair difficulty, signal integrity issues, flexibility, and temperature range make it less suitable for some applications.

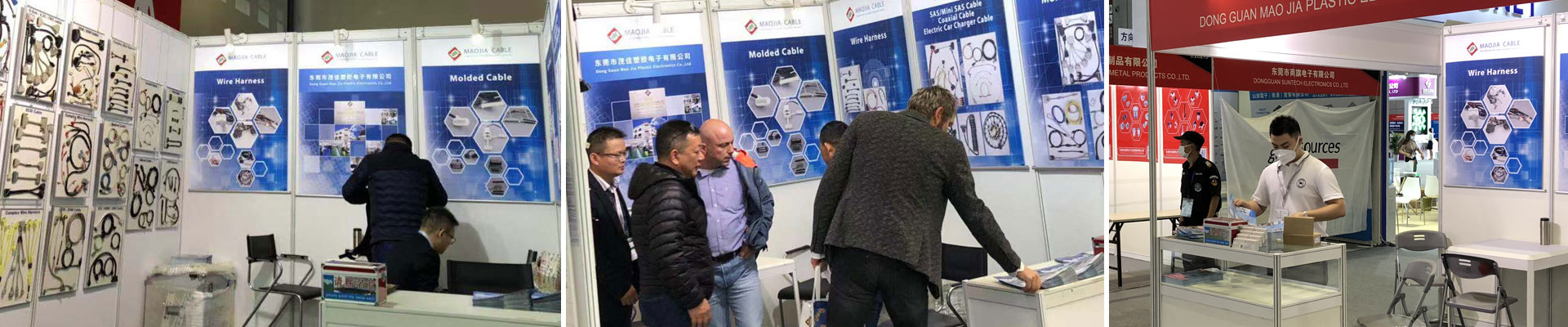

If you need to customize flat cable, please contact the professional cable manufacturer - Maojia.