- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2022-09-14 Origin: Site

Whether you are an electronics designer, electrical or mechanical engineer, purchasing manager, or in selecting a connector supply chain, selecting the suitable D-Sub housing for your application is critical.

Then Adam engineers, based on 15 years of professional d-sub connector experience, talk about how to choose D-sub connector housing according to the application.

There are many options and combinations of D-Sub housings, and it is essential to find the most suitable type for your scenario application. This article covers everything you need to know to help you choose the perfect D-Sub connector housing based on the answers to a few simple questions.

When choosing a material, you have several options.

▪ Die-cast metal - nickel

▪ Die-cast metal - black

▪ Metallized Plastic

▪ Black plastic

▪ Gray plastic

▪ Plastic - various colors

The material you choose may depend on the needs of the application. While plastic D-Sub enclosures are less expensive, they are not as durable or resistant to harsh environments as die-cast metal options. More resilient material such as metalized plastic or die-cast metal is preferable for cables that may require many mating cycles or be exposed to excessive noise in demanding applications.

If your application is only static and not frequently disconnected, a plastic enclosure may do the job. One advantage of colored plastic enclosures is the ability to design cables based on color coding and receptacles, making installation easier.

Choosing the suitable d-sub connector housing based on the field application of the cable?

Think about how the cable and receptacle will be used in the field application and how much clearance there may be behind the receptacle. The typical clearance space and the cable's flexibility can help you determine the best cable entry or exit angle.

For cable in/out connections? For applications is better to go with a sharp angle for applications that do not have much clearance behind them.

Options for cable entry or exit angles are 180° (straight), 90°, 60°, 45°, 40°, or 35°.

What mounting accessories will you use to mount the D-SUB connector housing?

Because of their importance in protecting connections and signal transmission, mounting D-Sub housings must be fixed and stable. There are many options for the correct mounting hardware, including.

Standard mounting hardware

#4-40 mating screws

#4-40 hand-tightening screws

Mechanical strain relief

Compression strain relief

Additional mounting hardware

▪ M2.5 screws

▪ M2.6 screws

▪ M3 screws

▪ Slide lock

▪ Quick lock post

▪ Washers

The mounting hardware you choose may depend on the socket configuration you want to connect. We recommend standardizing mounting hardware and sockets across your product line whenever possible for interchangeability, connection/disconnection, and support for greater efficiency.

In most cases, standard installation hardware is sufficient to complete the job. We also recommend using mechanical or compression strain relief devices if cables, sockets, or other cabling system components may be in motion or have strain applied to them. Mechanical strain relief hardware requires tools to assemble, while compression strain relief is not required.

Do you have any special requirements for the D-SUB housing hardware?

Finally, you need to determine if there are any special requirements, such as:

▪ Handling high loads, currents, and voltages.

▪ Handling coaxial contacts or another specialized wiring.

▪ Particularly delicate cabling requires maximum strain protection.

▪ Any other exceptional circumstances.

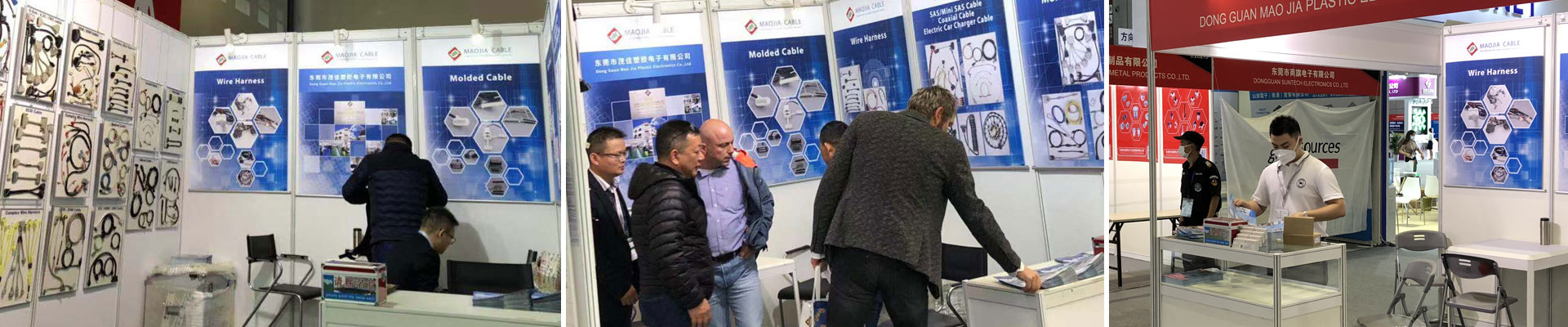

The above is the knowledge guide on how to choose D-sub connector housing according to the application. If you still don't understand anything about the above issues, or suppose you have need for purchase D-sub cable, please leave a message or send an email to contact us, professional D-SUB cable manufacturer - Maojia Cable.