- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 8 Author: Site Editor Publish Time: 2022-12-09 Origin: Site

Anyone with a boat would do well to understand the difference between marine cable and other wire classes. They are two completely different types of wire, and it is dangerous not to use them interchangeably.

What is the marine cable?

Marine wire, also known as marine grade wire or marine cable, is a highly flexible, special cable made of high strand count, individually tinned copper conductors.

Marine cable is made with a high conductor count to maintain extra flexibility. This allows it to make the bends and curves needed to snake through a boat's interior recesses and achieve tight connections.

The conductors of marine grade wire are individually tinned, which enhances its corrosion resistance and protects it from saltwater environments.

1. Do not use automotive-grade battery cables on boats - marine wire applies

If you ever install batteries on a boat or need to replace battery cables, use something other than an automotive-grade cable instead of marine wire.

First, it may need to be more flexible in the proper gauge to make connections. But more importantly, automotive-grade conductors are treated with a different complex and thorough corrosion protection than marine cables.

Any point of exposed copper wire - no matter how small - can erode quickly, and corrosion can spread like fire along the underside of the wire's insulation.

If the cable corrodes sufficiently, it can cause engine starting problems or leave you dead in the water.

Take your time; never use automotive cables on boats - use only marine cable and cable.

2. Use marine-grade terminals at connections

Marine-grade terminals are made up of tinned copper lug terminals. These terminals are designed for use in the marine environment and have certain characteristics, such as marine wire, that make them more suitable for use around water.

Most importantly, marine-grade terminals have corrosion-resistant tinned lug lugs. These will last longer; if you use terminals with untinned lugs, they will erode, and you will eventually make a new connection. Spend a few extra dollars and use the correct terminal connections the first time.

Marine-grade terminal connections also typically have closed front lugs to keep water out.

Remember to use crimping, not just soldering, to connect the terminal and the battery when laying marine cables. Crimping provides a stronger mechanical connection between the battery and the terminals. Alternatively, you can solder them, but remember always to crimp first and then solder. (This follows the ABYC connection guidelines and does not accept soldering as the only method of making electrical connections).

3. If using heat shrink tubing, use marine grade heat shrink tubing

Although marine cables are highly resistant to corrosion, we still need to lay the cables away from places where there is water or easily submerged water. After all, water is the natural enemy of any circuit or electronic system. Even if the marine cable has strong anti-corrosion ability, long-term contact with water will always increase the hidden danger of the circuit system. If you are going to use heat shrink tubing to cover the exposed areas of electrical conductors, use marine grade heat shrink tubing, not the regular grade.

Marine-grade heat shrink tubing usually contains a liner made of an adhesive that melts and bonds to the wire when heated. This creates a waterproof (or nearly waterproof) sheath around the wire and helps keep water out.

With small steps like these, you can waterproof the electrical components of your boat today and avoid expensive, time-consuming wiring tomorrow.

4. Use the right size wire (consult an electrical engineer, experienced boater, or manufacturer for specifications)

It is important to remember that it is impossible to use wire that is too large for the circuit, but it is easy to use wire that is too light, which can be very dangerous.

Using too small for the circuit can cause the wire to overheat, which can melt the insulation and potentially cause a fire - dangerous anywhere but catastrophic at sea.

It's also important to remember that as the length of the wire increases, the larger the gauge needed to complete the circuit.

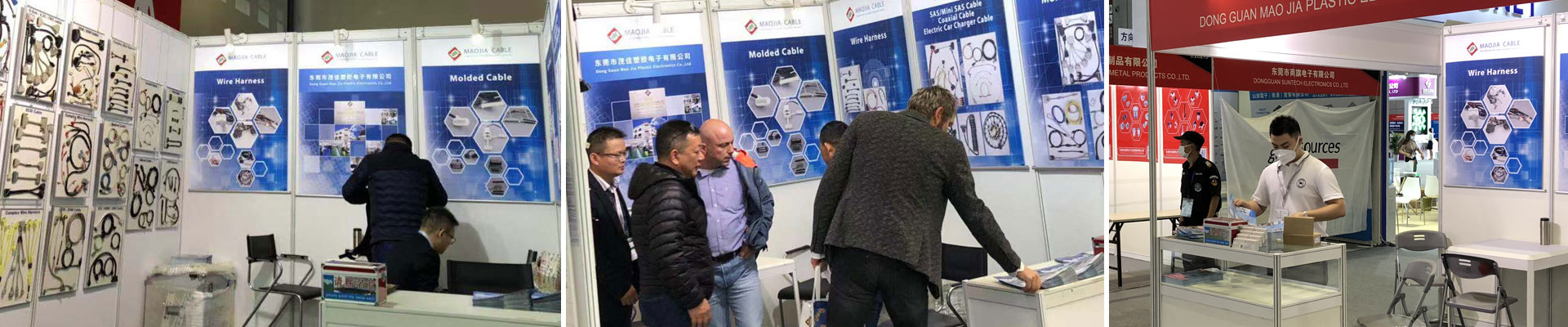

These are the 4 things you need to know about marine cables if you have other questions about marine cables you want to know or want to customize marine cables, welcome to contact Maojia - a professional marine cable supplier manufacturer.